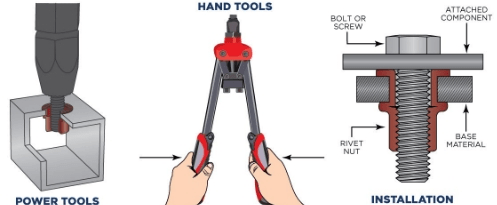

You ever fiddled with a rivet nut that just wouldn’t take? It's frustrating. It is crucial to do it fast and right. Enter the new rivet nut installation tools. They are transforming how things are manufactured and assembled. We’ll look at how these innovations accelerate the process, enhance accuracy, and simplify the job.

Developments in Rivet Nut Installation Hand Tools

Manual rivet nut Tools have existed for many years. But they’re improving a lot. So lets look at some updates that are making the process better.

Ergonomic Hand Riveter

These are all comfort tools. They're designed to help mitigate strain.

Features: The new contoured grips fit your hand better. Less weight makes them easier to handle. Stronger leverage means less effort expended.

Benefits: Work for longer without getting tired. They multiply what you can accomplish in a day. Great for smaller projects.

Ergonomic designs help you avoid aching hands and arms. Perfect for precision on projects where you need them.

Adjustable Stroke Hand Tools

Stroke adjustment is key. It’s easier than ever thanks to new tools.

Advantages: Suitable for various material thicknesses. Setting optimized for all the time give you a perfect fit. Reduces damage to materials.

Use Cases: Applies to thin sheet metal and composites. Perfect for auto repairs, construction, and much more.

These tools allow adjusting the amount of force you apply. This is perfect for delicate items.

PTI — Power Tool Innovations of Note for Rivet Nuts

The use of powered tools is taking rivet nut installation to a whole new level. They allow for higher efficiency and power. Lets check out the advances.

Cordless Rivet Nut Tools

Cordless tools are all about liberation. You can use them almost anywhere.

Advantages: Brushless motors have a longer lifespan. Batteries discharge in hours. Sizes are easily changed with the quick-change mandrels.

Applications: Ideal for site work, remote locations, and large projects. Some construction sites or assembly lines could help.

There is no tool as portable as these. No more lugging cords around.

Pneumatic Rivet Nut Tools

Pneumatic tools pack a punch. They are formidable and fast animals.

Specifications: Light designs minimize fatigue. Energy savings through a more efficient air. Precise force control enables consistent results.

Pros: The thread nuts go on remarkably quickly. If you do the same thing, you make fewer mistakes. Good for high-volume production.

At the same time, these are perfect for factory settings where speed is paramount. They also provide you with dependable performance.

Using Automation and Smart Technology for Rivet Nut Installation

Automation is doing everything different. The latest in smart tech is making your rivet nut installation even smarter.

Robotic Rivet Nut Systems

The robots are taking over the assembly lines. They can work all day.

Sensor: The built-in sensors guarantee the correct position. They keep it moving with automated feeding systems.

Advantages: Higher speed of production, improved quality control, and reduced size of labor expenses.

That's where robots come in, offering unmatched precision. These systems are investments that pay for themselves.

Data Logging Almighty Rivet Nut Tools

These devices, everywhere, document and capture all. They give you feedback on the fly.

Functionalities: Live updates on the force and depth of installation. Data quality control storage and analysis

Pro: Higher quality assurance, traceability, preventative maintenance.

Understand precisely what occurred with every rivet nut. These are the tools that prevent you from making mistakes before you make them.

Rivet Nut Mandrel form Material and Design Innovations

Mandrels, are a small but crucial part. They're getting better too.

This is about a combination of mandrel materials.

Stronger mandrels increase longevity. They offer dependable performance.

Materials: Wear-resistant hardened steel alloys. Mandrels with a specific coating lower friction in a process.

Advantages: Longer running, longer tool life and consistent in tooling performance.

Thus, investing in quality mandrels will save you money in the long run. They wont break easily.

Quick-Change Mandrel Systems

Faster than ever to swap mandrels — longer integration for smooth operation. This makes a big difference.

Easy changes with tool-free designs. Standardized APIs provide backward compatibility. Mandrels are securely held by magnetic retention.

Advantages: Reduced downtime, easier maintenance, and greater efficiency.

Back in the day changing mandrels used to stink. It’s also how these new systems make it easy.

How To Choose The Correct Rivet Nut Installation Tool

Choosing the right tool is half the battle. (Roles you are performing should be contemplated.)

Considerations Specific to Applications

Match your tool to the job. Every project has different requirements.

Elements: Thickness of material, rivet nut diameter, number of installations and environmental conditions.

Actionable Tip: Know what you’re gonna need before you buy it.

Is it thin metal or thick composites? Both speed and precision — but which one do you need more? These questions will steer you.

Cost-Benefit Analysis

Think about the long term. So don’t only check the price tag.

Factors: Upfront investment, running costs, productivity and quality improvements.

Actionable Tip: Add up the total cost of ownership.

A pricier tool could keep your costs down in the future. Consider the value it brings.

Conclusion

Industrial engineers– with websites that can already build rivet nut installation tools on demand– are getting smarter. These advancements increase speed, accuracy and usability.

What's next? Expect even more automation. Maybe self-adjusting tools. Rivet nut technology has a positive perspective.

In the market for an upgrade to your toolkit? Check them out to see how they can benefit your projects.

Language

Language