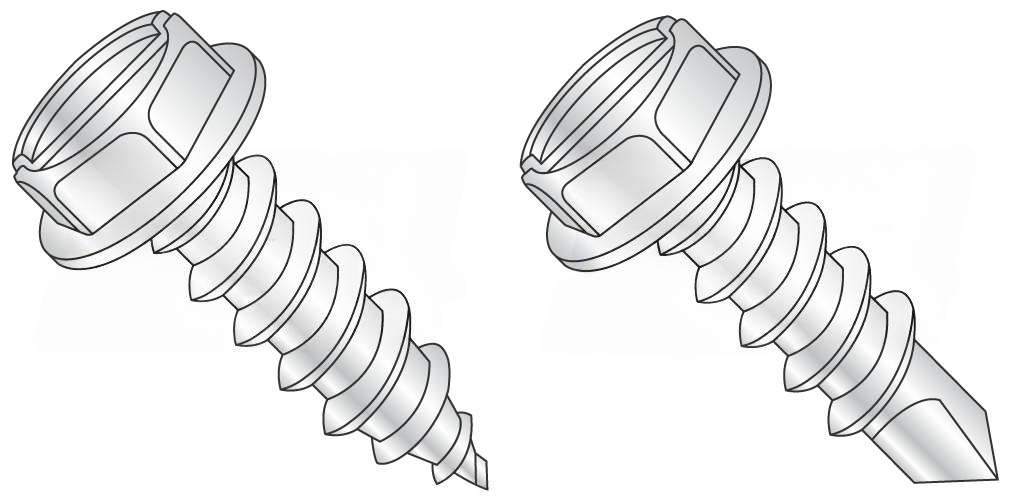

Self-drilling screws and self-tapping screws are two popular types of fastening materials in construction. While both are designed to simplify and expedite the process, they serve different functions and come with their own design features and ideal use cases. Here is a quick comparison so that you can determine when to use each screw type for your projects.

What Is a Self-Drilling Screw?

Self-drilling screws have a drill bit on the tip that allows them to drill their own hole when driven into the material. This quality makes these screws perfect for use on metal, wood, and plastic where a pilot hole would otherwise be needed.

Key Features:

Drill Tip: The tip is a welded drill bit making the screw able to drill its own hole without pre-drilling a pilot hole.

Fast Installation: They drill their own hole therefore save time over traditional screws that need pre-drilling.

Common Materials: Self-drilling screws are commonly used in sheet metal, HVAC systems, metal roofing, and other applications that require fastening metal.

Applications:

Metal roofing and siding

HVAC installations

Steel and metal fabrication

Electronics and appliances

What Is a Self-Tapping Screw?

Also get used to metal self-tapping screws, which have a pointed, sharp tip to cut grooves in a pre-drilled hole for better attachment. They do not have a built-in drill bit like self-drilling screws, but they are used in plastic, wood, or softer metals.

Key Features:

Thread-Cutting Action: These screws create threads as they screw into a pre-drilled hole, creating a snug fit.

Application: They are usually employed in comparatively softer materials like, wood, plastic, or aluminum.

Requires a Pre-Drilled Hole: In contrast to self-drilling screws, self-tapping screws need a pilot hole to be drilled into the material (though some can thread their own hole in thin materials).

Applications:

Woodworking

Plastic assembly

Light-duty metal applications

In addition, Electronics And Electrical Components

Self drilling vs Self tapping Screws: Compare & Contrast

Functionality:

Self-Drilling Screw: Has the ability to drill its own hole and tap the threads as it is inserted.

Self-Tapping Screw: Needs a hole to be drilled to tap through the thread into the material.

Tip Design:

Self-Drilling Screw: These screws feature a tip similar to that of a drill bit.

Self-Tapping- Has no drill bit but sharp point.

Material Suitability:

Self-Drilling Screwbest for metals and thicker material.

Self-Tapping Screw: Works best for softer materials like wood, plastic, and thin metals.

Ease of Use:

Self-Drilling Screw: Quicker and more effective as there is no requirement to make pilot holes.

Self-Tapping Screw: Not as efficient in creating threads, self-tapping screws do require pre-drilling.

Applications:

Self-Drilling Screw: Employed in construction, metal roofing, and fabrication.

Self Tapping Screw Used for light-duty projects such as woodworking electronics and plastic assembly

What Screw Should You Use?

For Metalworking: If you happen to work with metal, including thicker sheets or metal roofing, a self-drilling screw is probably the best route for you.

For Wood or Plastic: For use with wood, plastic or thin metals, and if you don’t wish to pre-drill a hole, a self-tapping screw would be better.

Submit for an Online Quote:

Send us (sale803@jiliang988.com) the completed form along with your drawing, and we’ll provide you with a fast and competitive quote.

If you have any questions or need assistance, feel free to contact us. We’re here to help!

Language

Language