Learn that custom machine screws are in your phone, your car and even your glasses? These tiny pieces of our lives hold us in place. So, really, let’s take a look at these unsung heroes. There are several reasons why custom machine screws are important. Choosing the proper screw is imperative for a success project.

Machine Head Screw Style Overview

Machine screws come in a variety of head styles that are suited for different applications.

The head of a screw matters. It determines the orientation of the screw and the sort of tool required. Each style has advantages. Let us take a look at some of the common types.

Flat Head Screws

Countersunk design, flat head screws. That means they sit flush with the surface. They’re excellent for a polished appearance. You see them in furniture and electronics. One disadvantage? They’re often more difficult to install.

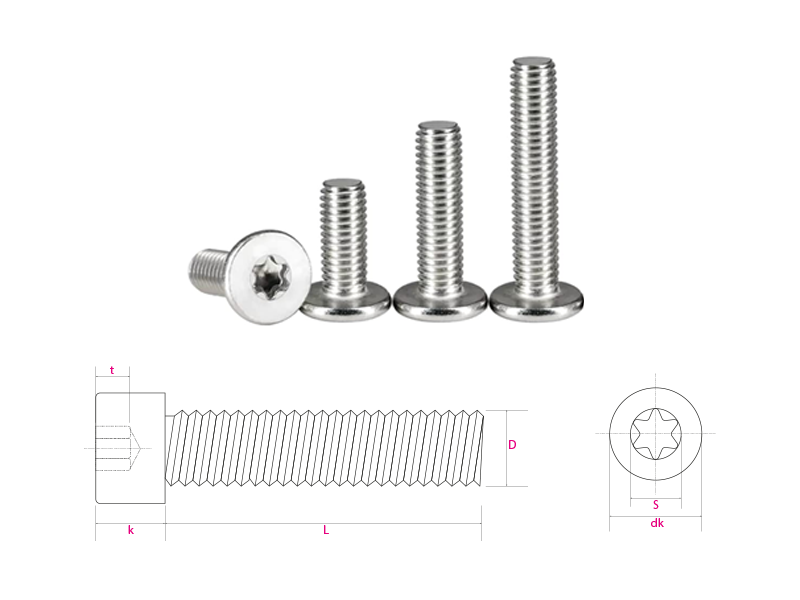

Pan Head Screws

Phillips pan head screws have a slightly domed top. They are incredibly flexible and convenient to use. These are the screws you use for the broad range of fastening. They are often used in machine building. Pan heads are the way to go if you want something versatile and dependable.

Button Head Screws

Low Profile — Button head screws are low profile. They give a clean, finished appearance. These things are good for decorative panels. You will find them in architectural hardware. They look good!

Material Choice for Custom Machine Screws

What the screw is made of also matters. Each material will have its own properties. Let's consider a few options.

Stainless Steel Screws

Corrosion is resisted by stainless steel. It's strong and reliable. Some grades are 304 and 316. These are beneficial in marine environments. They are also used in food processing.

Carbon Steel Screws

They are also known for high strength. It can be heat-treated. However, it can rust easily. Use it where strength is key. This is used in automotive and construction projects.

Alloy Steel Screws

Alloy steel is super strong. It resists wear and tear. It is also quite suitable for high-performance applications. Aerospace or heavy equipment comes to mind.

Machine Screws — Customization Options

There are times when regular screws just won't be enough. Custom options provide you with a lot of flexibility. What are your choices?

Special Length and Customize Thread Pitch

Need a specific screw size? Custom lengths are possible. Unique thread pitches, too. There are standards for the sizing of threads. Ensure your supplier is aware of them.

Specialized Coatings & Finishes

Coatings protect screws. Zinc plating fights rust. One is black oxide for a sleek appearance. Color and protection are added by anodizing. The proper finish—makes a difference!

Unique Head Designs

Others require specialized heads. Tamper-proof designs essentially bar tampering from occurring. Recessed heads for a clean look. Consider the head, a key detail.

Sector-wise Applications of Custom Machine Screws

Custom screws are everywhere! They address specific problems in a variety of domains. Regular screws don’t always do the trick. Let’s examine a few use cases.

Automotive Industry

Engines need strong screws. None of this would be possible without reliable fasteners holding the interior parts together. The exterior panels have to remain secure. The Automotive Industry Uses Specialty Screws to Address These Needs

Electronics Industry

Circuit boards are delicate. Device housings need to be accurate. Must be precise component fixing. Custom machined screws are widely used in electronics.

Medical Device Manufacturing

Surgical devices have to be perfect. The implant needs to be built from biocompatible materials. Diagnostic devices need to be accurate. Custom screws are also used in medical devices.

When to Order and Source Custom Machine Screws

Choosing an appropriate supplier is essential. How do you get custom screws? Quality control, quality control is very key.

Finding a Reliable Supplier

Research suppliers. Check their certifications. Request samples to test. A good supplier is a partner.

MOQ: Lead Times And Minimum Order Quantities

Production takes time. Minimum orders might apply. Get a plan and understand the specifics. Ask about lead times!

Conclusion

Custom machine screws can be made with a variety of head styles and materials. They serve different applications. Take all considerations into account while completing your screws selection. Speak with specialists and seek out resources. Make sure you have the correct screw for the job!

Submit for an Online Quote:

Send us (sale803@jiliang988.com) the completed form along with your drawing, and we’ll provide you with a fast and competitive quote.

If you have any questions or need assistance, feel free to contact us. We’re here to help!

Language

Language